There are many ways to mount a CNC Broach Tool holder in your CNC Lathe or Mill. Here are some of the most common clamping methods we’ve seen over the years: A Hydraulic holder is the best method. Collet holders work well as long as the collet is longer than

Broaching Blog

What Is Broaching Keyways on a Lathe?

A simple way to cut internal keyways without moving the part Keyways are one of the most common internal features in machined parts, but for years, shops had to rely on secondary equipment like slotters, broach presses, or wire EDM to get them done. That meant extra setups, longer lead

What Are the Benefits of Broaching In-House?

Cut costs, reduce delays, and take full control of your production process Sending parts out for broaching adds risk, delays, and extra cost to your operation. Shops that bring broaching in-house don’t just save time. They improve quality control, increase margins, and become more competitive. Shops that make the switch

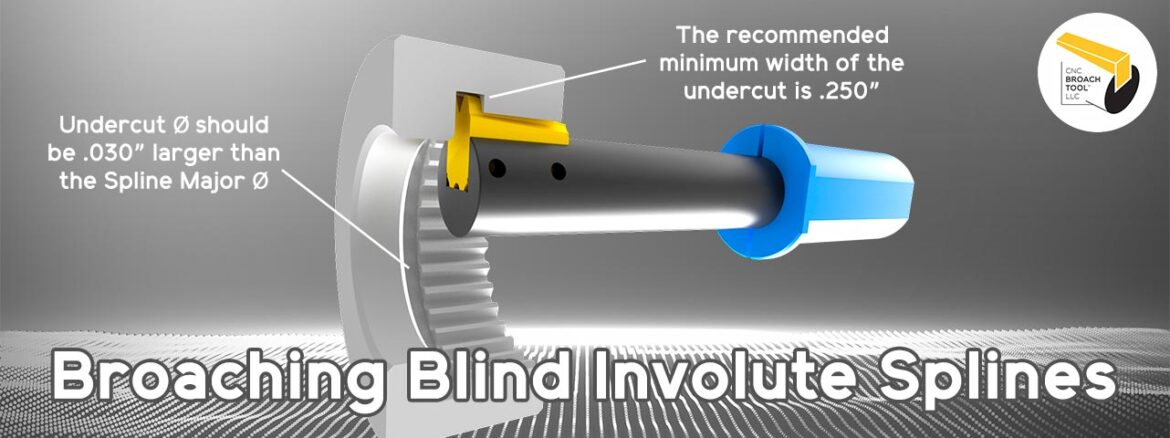

CNC broaching Blind Splines

Blind splines are internal splines cut inside a bore that does not pass completely through a part. Because the tool cannot exit the back of the hole, blind splines require careful planning, proper clearance, and accurate programming. With the right approach, CNC machines can produce blind splines reliably using a

CNC Broaching Blind Keyways

Blind keyways are keyways machined inside a bore that does not pass completely through the part. Because the tool cannot exit out the back of the hole, blind keyways require proper planning, relief, and programming to avoid insert damage and to produce a clean, consistent slot. CNC broaching makes it

Is CNC Broaching Bad for Your Mill or Lathe?

It’s a common question among machinists new to broaching on CNC machines: will broaching damage my mill or lathe? The concern is understandable. Traditional broaching is known for heavy cutting forces and specialized equipment, so the idea of broaching inside a CNC can sound risky. The truth is that when

What is Spline Broaching?

Spline broaching is a machining process used to create a series of grooves or teeth, known as splines, on the inside of a bore or along the outside of a shaft. These splines form a drive connection between two mating parts, allowing torque to be transmitted while maintaining alignment. The

What is Keyway Broaching?

Keyway broaching is a machining process used to cut a slot, called a keyway, inside a bore. A keyway is a groove that allows a key to fit between a shaft and a mating part such as a gear, pulley, or coupling. This slot-and-key connection locks components together, transmitting torque

What is Broaching?

Broaching is a machining process used to cut internal or external shapes by pushing or pulling a specially designed tool called a broach across a workpiece. Unlike traditional cutting tools that may require multiple passes or secondary operations, a broach tool removes material in a single, progressive motion. Each tooth

How to Optimize Broach Depth of Cut to Extend Tool Life

CNC Broach Tools G-code Program Generator V2 Broaching is one of the most efficient processes for creating precise internal features such as keyways and splines. Yet, tool life in broaching often seems unpredictable, with many shops relying on trial-and-error settings that can lead to premature wear or poor finishes. The

How to Broach Tapered Keyways in a CNC Machine

Tapered keyways present unique challenges when it comes to broaching on a CNC machine. Unlike straight keyways, the taper requires careful planning to avoid insert interference, depth errors, or tool damage. At CNC Broach Tools, we want to outline the best practices to help machinists achieve clean, accurate results while

Contact Us

Contact Us (877) 248-1631

(877) 248-1631