Home

Visit our CNC Broaching Blog

CNC Broaching Program Templates FREE

Keyway Slotting Tool Size Chart

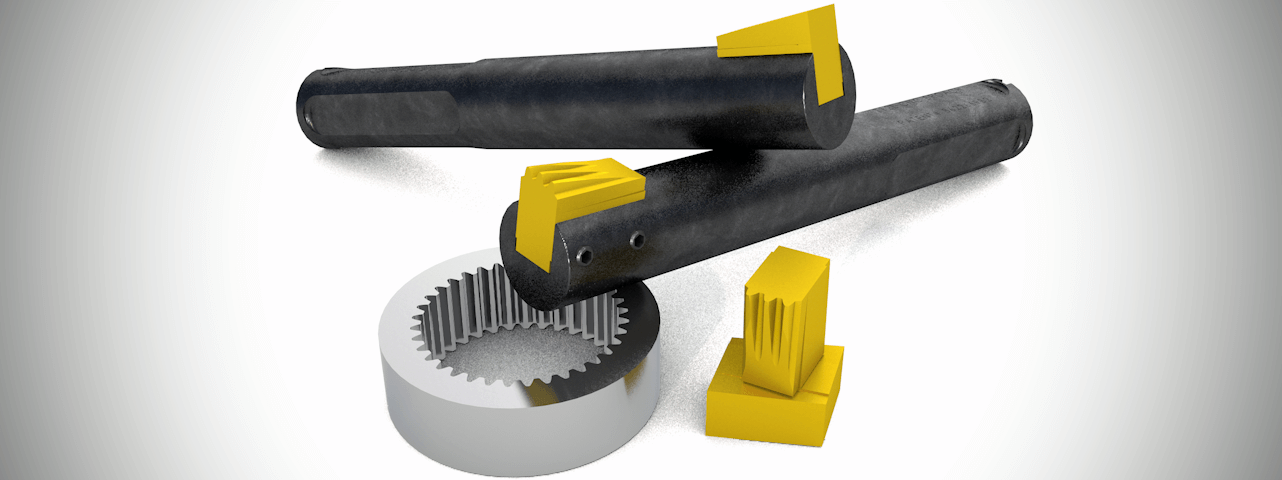

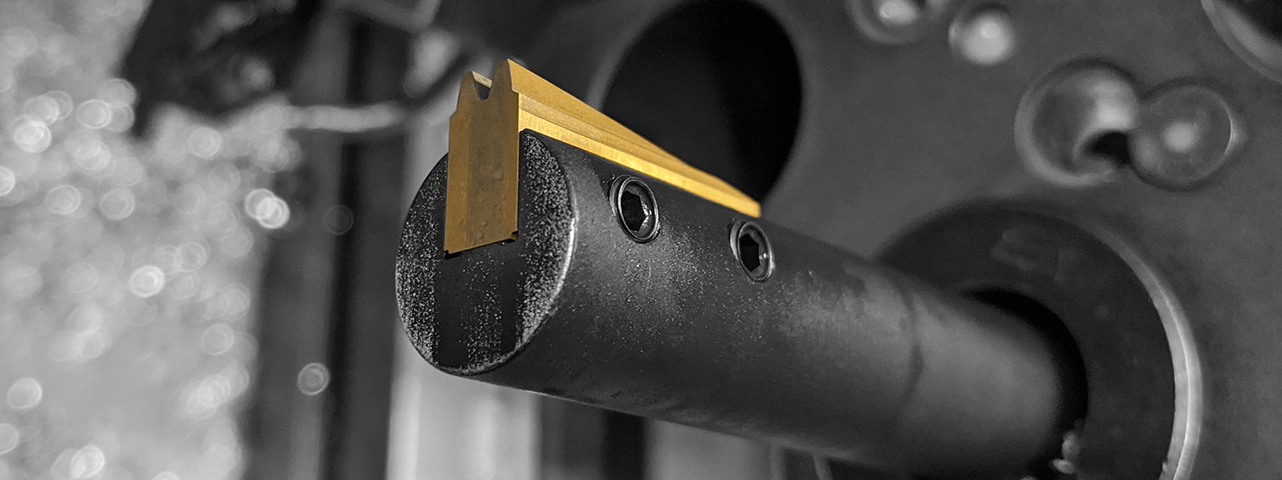

CNC Broach Inserts have

TWO Carbide cutting edges

WATCH CLIENT TESTIMONIAL

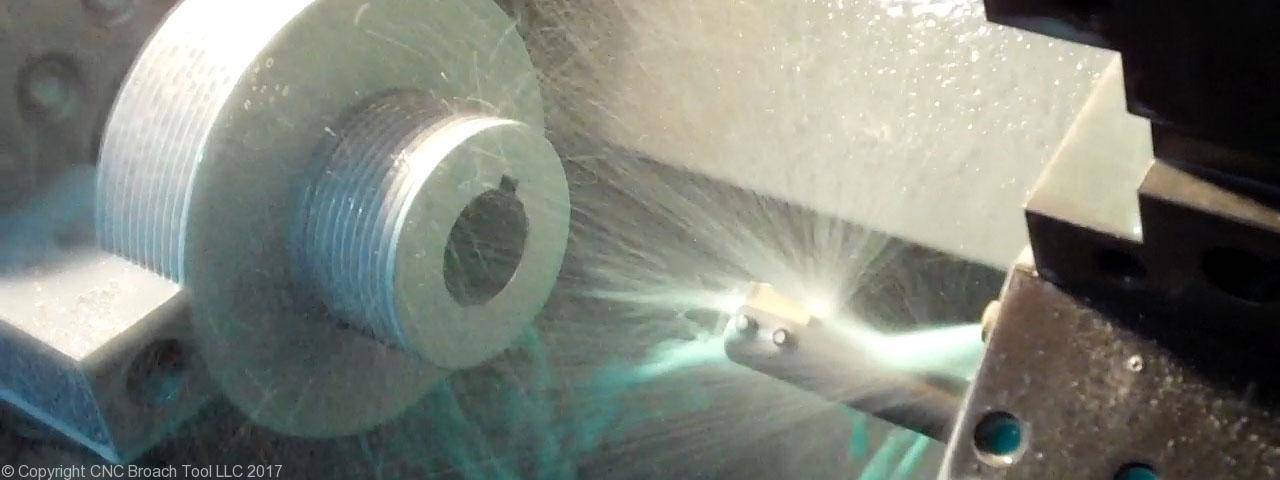

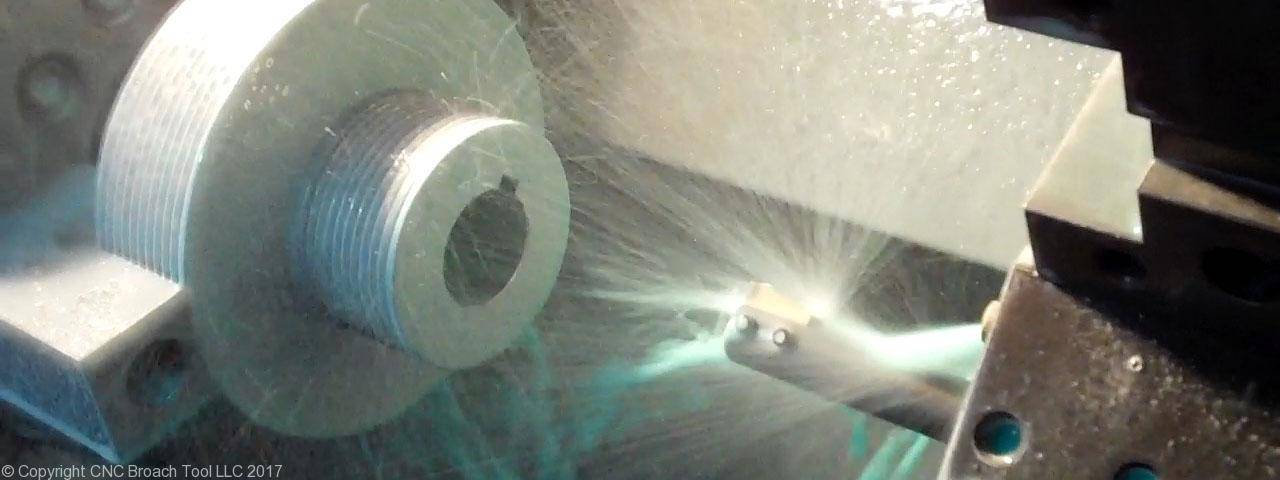

CNC Keyway Cutter Broaching 304 Stainless

WATCH CLIENT TESTIMONIAL VIDEO

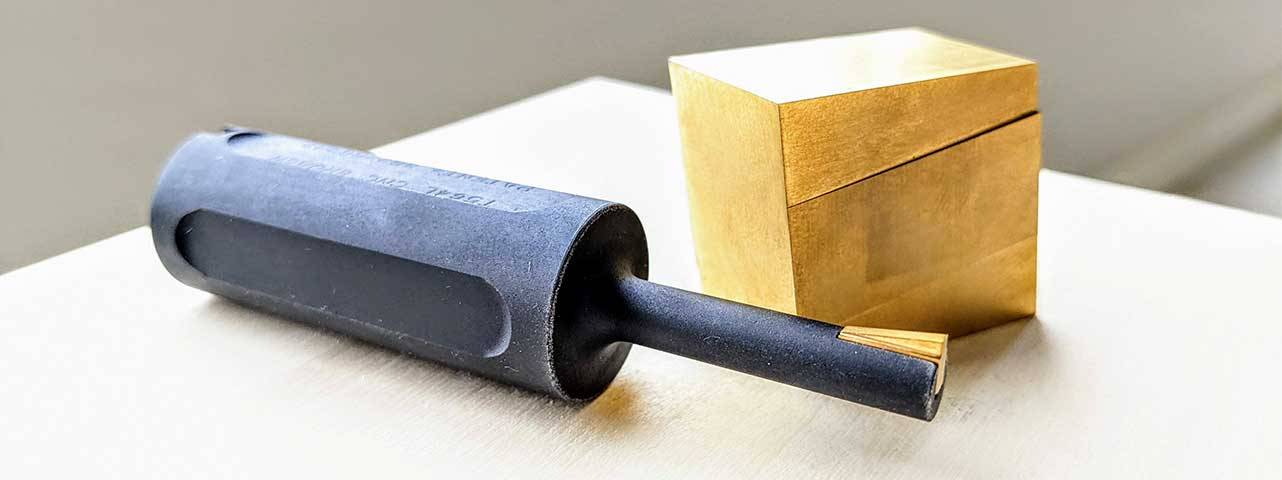

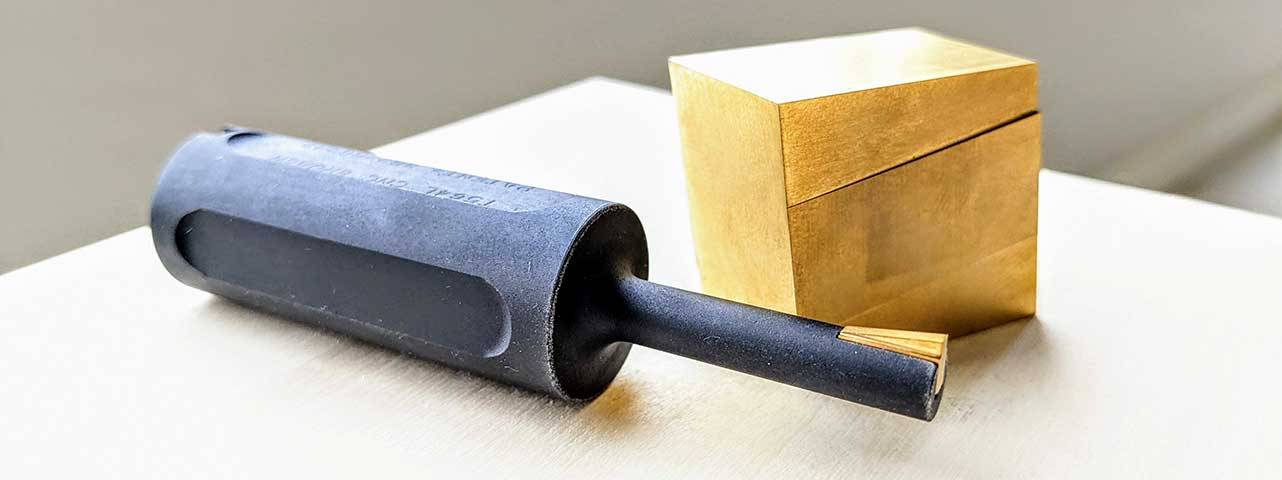

Keyway Broaching Tool for CNC to cut blind internal keyway

CNC BROACH TOOLS ENABLE CNC LATHERS AND MILLS TO BROACH INTERAL

KEYWAYS RATHER THAN TRANSFER PARTS TO A SEPARATE BROACHING MACHINE,

VEND OUT THE KEYWAY BROACHING OPERATION, OR EDM THE KEYWAY

- CNC BROACHING ALLOWS YOU TO FINISH THE PART COMPLETE ON ONE MACHINE

- BLIND HOLE BROACHING ON YOUR CNC MACHINING

- CARBIDE INSERTS HAVE TWO CUTTING EDGES

- INSERTS CAN BE RE-GROUND MULTIPLE TIMES

- QUICK CHANGE INSERT KEEPS BROACH TOOL ON CENTER IN MACHINE

BEFORE contacting us for rfq please visit

the keyway broach tools page

Broaching keyways is not a 2nd operation!

CNC KEYWAY CUTTERS ELIMINATES THESE STEPS

- NOT WAITING ON AN OPERATOR

- NOT SETTING UP ANOTHER WORK CENTER

- NOT HAVING TO PUT PARTS IN A BIN WITH A SEPARATE PART NUMBER

- NOT MAKING SUREALL TOOLING AND FIXTURING IS AVAILABLE FOR ANOTHER WORK CENTER

- NOT SETTING UP A PART ON CENTERLINE THAT JUST CAME OUT OF THE CNC LATHE-FOR A THOUSAND PARTS!

CNC COOKBOOK, THE INTERNETS MOST POPULAR CNC BLOG, WRITES ABOUT USING CNC BROACH TOOLS FOR MILL BROACHING

HTTP://BLOG.CNCCOOKBOOK.COM/2014/11/06/BROACHING-CNC-MILL/

AN OFF-THE-SHELF SOLUTION FOR THE CNC BROACHING OF STANDAR INTERNAL KEYWAYS.

KEYWAY BROACHING IS ONE OF THE MOST SHOCKING OPERATIONS IN MACHINING.

CNC mill broaching and cnc lathe broaching allows yet another operation to be completed on your machining center rather than moving parts to a separate key-seater, EDM or broaching machine, vending out the operation to an expensive broaching house, or using valuable shop time making your own tools.

Keyway broaching is one of the most shocking operations in machining and this has prevented previous inserted broach tool designs from standing up to the forces required to broach internal keyways. With clients around the world, our broach tool design is proven to stand up to long production runs in any material the machining world uses. Using CNC Broach Tool keyway cutters clients broach in titanium, 8620, inconel, 4140, 304 stainless, monel etc…read some of the client testimonials throughout the website.

We offer an off-the-shelf solution for the CNC broaching of blind or through internal keyways. Some of the many benefits of broaching on your machining center include finishing a part complete in one location which enables you to ship parts complete when they come off of your lathe or mill. Additionally the cost savings calculated when using CNC Broach Tools must include negating the shop time needed to transport parts to a separate machine and set them up on center before broaching the “old school way”. Blind keyways have long been a problem usually involving an expensive, time consuming, die sink operation but as long as you have a relief groove or cross hole, blind keyways can be broached in a cnc mill or lathe with CNC Broach Tools.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631