To Broach Internal Blind Keyway’s with our Keyway Broach Tools you must have a groove or cross hole relief or you will most likely crash the broach tool.

Our entire selection of standard tools and inserts can be found below. Driven Unit holders can be found here.

Downloadable Broach Tool Dimensions & Keyway Broach Insert Chart PDF

In Stock

Broach Tool Dimensions

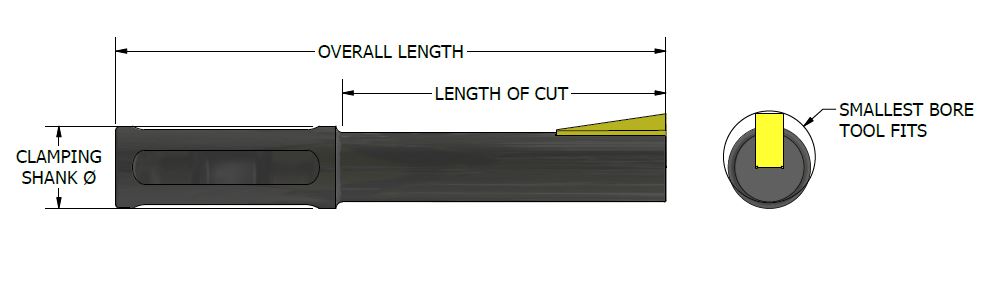

| Part No. | Holds Inserts For Keyway | Length of Cut (LOC) | Overall Length | Clamping Shank Diameter | Smallest Bore Tool Fits |

|---|---|---|---|---|---|

| T564L | 3/32", 2mm, 5/64", 1/16", and 1.5mm | 1.10" | 3.225" | 0.750" | 0.310" |

| T332L | 3/32" | 1.12" | 3.25" | 0.750" | 0.377" |

| T18L | 3mm or 1/8" | 1.57" | 3.7" | 0.750" | 0.500" |

| T158SM | 4mm or 5/32" | 1.57" | 3.7" | 0.750" | 0.466" |

| T4MML | 4mm or 5/32" | 2.37" | 4.5" | 0.750" | 0.575" |

| T316L | 3/16" | 2.62 | 4.75" | 0.750" | 0.600" |

| T5MML | 5mm | 2.62" | 4.75" | 0.750" | 0.600" |

| T6MML | 6mm or 15/64" | 2.94" | 5" | 0.750" | 0.745" |

| T14L | 1/4" | 2.94" | 5" | 0.750" | 0.835" |

| T516L | 8mm or 5/16" | 2.94" | 5" | 0.750" | 0.880" |

| T38L | 3/8" | 3.95" | 6" | 0.750" | 0.967" |

| T38SM NEW | 3/8" | 2.95" | 5" | 0.750" | 0.967" |

| T12L | 1/2" | 4.25" | 7" | 1.000" | 1.360" |

| T58L | 5/8" | 6.25" | 9" | 1.25" | 1.685" |

| T75L | 3/4" | 8.25" | 12" | 1.500" | 1.994" |

In Stock

Keyway Broach Insert Chart

| For Keyway Width | Part Number | Insert Width Tolerance | Height of Groove (HOG) | Fits Broach Tool Holder |

|---|---|---|---|---|

| 1mm | N1MM | 0.041" +.001/-.000 | 0.052" | T564L New Tool |

| 1.5mm | Bi-59 | 0.059" +.001/-.000 | 0.052" | T564L New Tool |

| 1/16" | N116 | 0.064" +.001/-.000 | 0.052" | T564L New Tool |

| 5/64" | N564 | 0.079" +.001/-.000 | 0.052" | T564L New Tool |

| 2mm | Bi-080 | 0.080" +.001/-.000 | 0.052" | T564L New Tool |

| 3/32" | Bi-94 | 0.094" +.001/-.000 | 0.052" | T564L New Tool |

| 3/32" | N96 | 0.095" +.001/-.000 | 0.052" | T564L New Tool |

| 1/16" | N64 | 0.064" +.001/-.000 | 0.075" | T332L |

| 2mm | N2MM | 0.080" +.001/- .000 | 0.075" | T332L |

| 3/32" | N332 | 0.0955" +/- .0005 | 0.075" | T332L |

| 4mm or 5/32" | Bi-160SM | 0.160" +.001/-.000 | 0.095" | T158SM not T4MML |

| 3mm | N3MM | 0.1195" +.001/-.000 | 0.100" | T18L |

| 1/8" | N126 | 0.126"+.001/-.000 | 0.100" | T18L |

| 1/8" | N18 | 0.127 +.001/-.000 | 0.100" | T18L |

| 4mm or 5/32" | N4MM | 0.158" +.001/-.000 | 0.120" | T4MML |

| 3/16" | 3N3316 | 0.188 +.001/-.000 | 0.125" | T316L |

| 3/16" | 1N1316 | 0.1885" +.001/-.000 | 0.125" | T316L |

| 3/16" | 2N2316 | 0.190" +.001/-.000 | 0.125" | T316L |

| 5mm | N198 | 0.198"+.001/-.000 | 0.125" | T5MML |

| 5mm | N5MM | 0.199" +.001/-.000 | 0.125" | T5MML |

| 6mm | N238 | 0.238"+.001/-.000 | 0.150" | T6MML |

| 6mm or 15/64" | N6MM | 0.239" +.001/-.000 | 0.150" | T6MML |

| 1/4" | N251 | 0.251"+.001/-.000 | 0.150" | T14L |

| 1/4" | N14 | 0.252" +.001/-.000 | 0.150" | T14L |

| 5/16" | N313 | 0.3135" +.001/-.000 | 0.200" | T516L |

| 5/16" | N516 | 0.3155" +.0005/-.0005 | 0.200" | T516L |

| 8mm | N316 | 0.3165" +.001/-.000 | 0.200" | T516L |

| 8mm | N8MM | 0.318" +.001/-.000 | 0.200" | T516L |

| 3/8" | N376 | 0.376" +.001/-.000 | 0.220" | T38L & T38SM |

| 3/8" | N38 | 0.377" +.001/-.000 | 0.220" | T38L & T38SM |

| 10mm | N394 | 0.394" +.001/-.000 | 0.280" | T12L |

| 7/16" | N439 | 0.439" +.001/-.000 | 0.280" | T12L |

| 12mm | N474 | 0.474" +.001/-.000 | 0.280" | T12L |

| 1/2" | N501 | 0.501" +.001/-.000 | 0.280" | T12L |

| 1/2" | N12 | 0.502" +.001/-.000 | 0.280" | T12L |

| 5/8" | N626 | 0.626" +.001/-.000 | 0.338" | T58L |

| 5/8" | N58 | 0.627" +.001/-.000 | 0.338" | T58L |

| 3/4" | N75 | 0.752" +.001/-.000 | 0.450" | T75L |

Contact Us for CNC Broach Quote

About Keyway Broach Tools

Our keyway broach tools are made from 17-4 Stainless and heat treated to 44Rc which avoids the brittleness of 60’s Rc and the flex potential of 20’s Rc. The long length of cut provided has been used and tested by thousands of machine shops and companies since 2006 when our patented broach tool design was sold through Razorform Tools. The same keyway broach tools and inserts that fit Razorform Tools are interchangeable with our keyway broach tools.

We do not do one-off special designs but instead rely on a decade old, standardized, proven product. When we send you keyway broach tools we know the same exact design you get is the same design that works for everybody else. The variables as to how well our keyway broach tools work for you are in your hands and mostly center around your set-up and programming. For tips on how to set-up your tool correctly visit this page of our website: https://cncbroachtools.com/keyway-cutters-speed-feed/

The concept of broaching needs to shift from, a crashing operation where large chunks of metal are gouged out to a “shaving” action at high speeds. This does not hurt your expensive CNC machine as the average depth of cut per pass is .001”. At .001” depth of cut your machine doesn’t even know it’s cutting. Every week we have a new client tell us that they were concerned about forces so they put an indicator on their spindle and the indicator barely registered. Average speeds are 300 inches per minute. Average cycle time per part 1.5-2 minutes depending on length of cut and depth of the keyway. If a longer length of cut is needed for your application CNC Broach has known many of our clients to braise a piece of bar stock to the butt of our keyway broach tools, turn it so both pieces are concentric and then clamp on the longer length. We’ve known many clients to extend their keyway broach tools out and get that extra inch or two to get the job done without the cost or time involved with a special broach tool.

Another option is for us to special grind the width tolerances down of an insert that fits into a larger, longer broach tool holder. That tool could then be used to do a longer and smaller keyway provided that that bigger tool will fit the smaller bore size that is commonly associated with smaller keyways. All Keyway Broach Tools shown are typically in stock and can usually be shipped same day UPS Red if needed.

About Carbide Inserts for CNC Keyway Broach Tools

We only sell TiN coated carbide inserts. We do not sell HSS inserts. Our carbide keyway cutters have two cutting edges per insert. So be sure to divide the cost by two to calculate the true value of the CNC broach system. Our inserts have been called very robust and rigid and when you hold one in your hand you’ll feel the weight of it. Many clients re-grind each cutting edge numerous times before the insert loses tolerance but this is not a service we provide. I have had clients tell me they re-grind each cutting edge 4-9 times. Again we do not offer a re-grind service.

Special Grind width tolerance

We do special grind the width tolerances on both cutting edges down.

Example: .0955” width special grind to .064” +.001/-.000

Special grinding the width tolerance is a minimum of three inserts, $20 grind fee per insert, and about 10-14 days to ship. We need at least one thousandths tolerance.

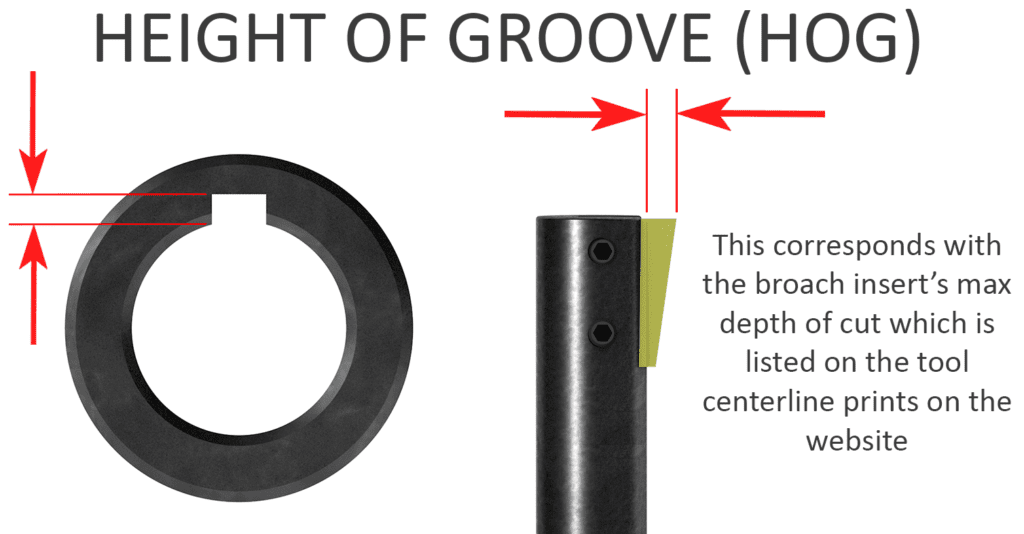

Understanding the Height of Groove Dimension

When using our keyway insert chart please always check the height of groove dimension. This is how high the insert sticks up above the tool to get the depth radially (not length).

This depth dimension is different than the “length” depth and usually is not called out directly on drawings but has to be calculated by subtracting the dimension of the centerline of the bore to the top of the keyway from the overall bore size. Many clients do not understand us when we ask them for the Height of Groove or “ceiling” of the keyway dimension. And when we ask them the depth they give us the length. So then we say, “the other depth” and confusion occurs. For clarity: A keyway or slot has three dimensions. 1) the width 2) the length (most people call this the depth, CNC Broach calls it the length to differentiate it)

3) the depth, or the depth radially, or the Height of the Groove, or the ceiling of the keyway

Please do not ask us to quote you insert life. How well our product performs is solely based on variables out of our control such as your set-up and programming. If you would like to see examples of insert life that other clients get there are many testimonials throughout our website that will give you an idea of what is possible with our product, here are a few client generated videos: Keyway Broach cutting 304 Stainless https://youtu.be/KF9XvW-Oh54 Broach Tool cutting 1215 Steel https://youtu.be/reErqhcUE7g Broaching Keyway in 8620 https://youtu.be/W3x5aRFctks

New CNC Broach Tool Series – Fits live lathe broach tooling from MD Tooling and M.T. Marchetti

When broaching a keyway in a tough 4140 motor shaft Baldor Electric Motors uses CNC Broach Tools. When they asked us to redesign the shank of our slotting tool to fit the MD Tooling live broaching tool we jumped at the chance. MD Tooling is the American distributor for M.T. Marchetti live lathe broaching heads. Their live tooling is great for high volume clients that want to improve cycle time. After modifying the rear shank of our broach tool the Baldor engineer informed us that we had, “blown PH Horn Broach out of the water” regarding insert life. We now carry eight keyway cutter tools that fit the holder for MD Tool and MT Marchetti slotting machine tools.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631