At CNC Broach Tools, we provide proven solutions for CNC keyway and spline broaching. Many machinists using Haas CNC mills ask us about program templates, so we’ve put together a Haas mill broaching program template to help guide you. This template is designed as a foundation to build from, not a one-size-fits-all solution.

Important Notes on Haas Programming

- Haas updates its CNC controls regularly, and available options can vary widely depending on the year and model of your machine.

- Machine tool builders may also add their own custom M-codes or functions.

- Because of these variations, no single program template can be guaranteed to work in every application.

Our team at CNC Broach Tools has decades of CNC machining and programming experience. While we do not provide custom programming services, we can help review programs and offer guidance if customers run into challenges.

For a reliable and automated solution, we recommend using our Keyway Broach Program Generator, which builds G-code specifically for keyways:

👉 CNC Keyway Broach G-Code Program Generator

For spline cutting, you’ll also find useful resources here:

👉 Broaching Involute Splines on CNC Lathes and Mills

Haas Mill Broaching Downloads

We continue to make these resources available for reference:

⚠️ Please note: These templates are a starting point only. Users must adapt the code for their specific machine, tooling, and options

Client Insight: Indicating the Broach

One of our customers, Joe from Drifton Precision Machining in Pennsylvania, shared this helpful tip:

“We were having trouble indicating the keyway broach square in our Haas Minimill. To orient the spindle, we used an M19 code. For whole-degree adjustments we used M19 PXXX, but when we needed less than a degree, we used M19 R45.05. Without the R code, the spindle would quiver and make indicating difficult. Once we figured this out, we had very good success.”

Thanks, Joe — great advice for anyone broaching on a Haas!

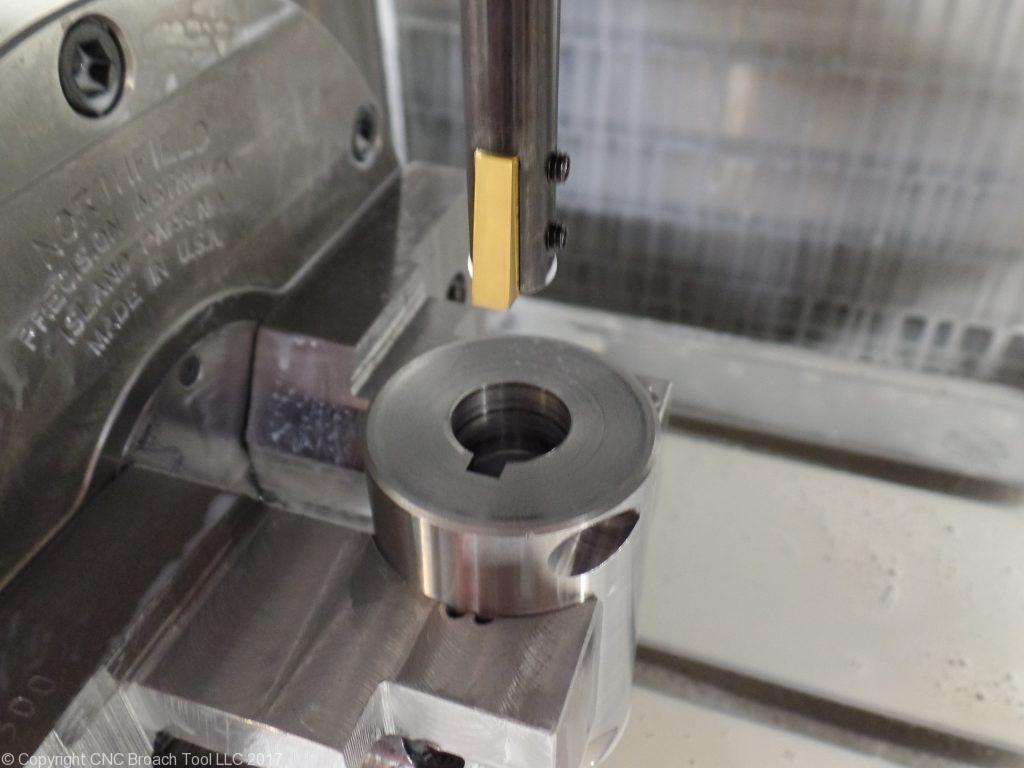

Haas Mill Broaching: Blind Keyways

When cutting a blind keyway on a mill, it’s important to keep in mind:

- Gravity is not helping chip evacuation.

- Material can pack into the relief area and cause a crash.

- A cross-hole relief is highly recommended because coolant can flush chips out both sides.

- A vertical groove relief can trap chips, increasing the risk of crashes.

👉 For more details, see our guide: Blind Keyway Broaching.

Common Programming Considerations

- M19 spindle orientation is standard on Haas, but adjustments for fine alignment may require decimal R values.

- Options vary depending on the Haas model and year of manufacture.

- Always verify if your machine requires special M-codes for feeding with the spindle stopped.

Our Keys to Programming CNC Broach Tools guide (included with the templates) provides more advanced slotting program details.

Disclaimer

This CNC Broach Tools program template is for informational and reference purposes only. It is provided without guarantees or warranty. CNC Broach Tool LLC makes no warranties of any kind, either express or implied. Use of this programming template is solely at the user’s own risk.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631