Understanding the Depth Radial Keyway Dimension

The Forgotten Keyway Broach Dimension: A keyway, internal or external, has three dimensions. However, when going over applications with clients for Internal Keyways CNC Broach Tools needs clients to provide us with four dimensions. Not the drawing, just four dimensions. They are:

1) The Width of the keyway and the specific width tolerance needed

2) The Bore size that the tool and insert must fit into

3) The Length of Stroke needed. Most refer to this as the Depth. Specifically it is the Axial Depth of the application.

4) and the forgotten keyway dimension, which is the Depth Radial Dimension

Historically, the standard for the Depth Radial keyway dimension is half the width of the keyway.

Example: a 3/16 width keyway typically should have a .090” – .100” Depth Radial Dimension

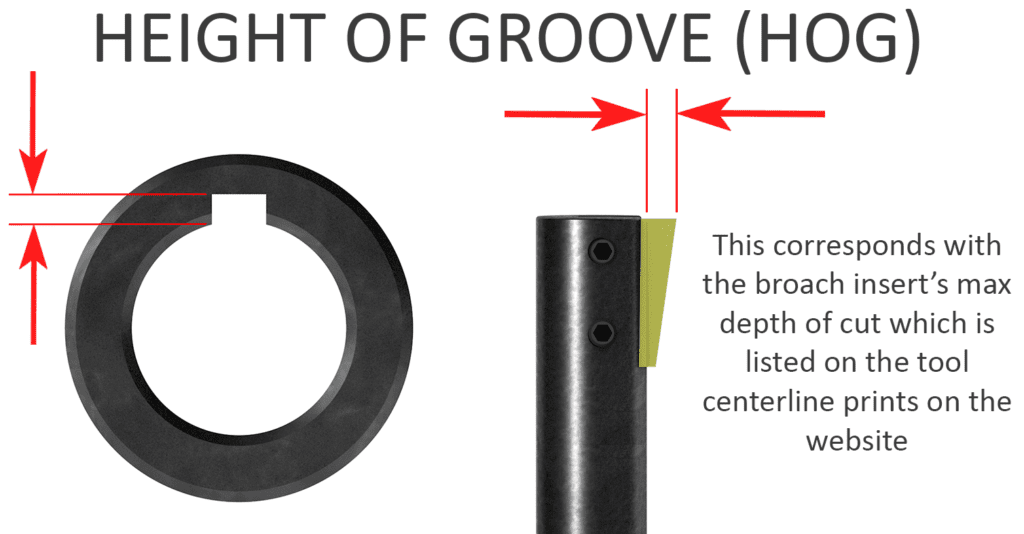

CNC Broach Tools coined a new machining vocabulary term calling the Depth Radial the Height of the Groove to differentiate it by terminology from the Depth Axially. Most of the clients that call give us the Length of Stroke Depth, or Axial Depth, instead of the Depth Radially when we ask for the Depth. Even when we ask for the Depth Radially they keep giving us the Depth Axially. It gets very frustrating for both parties when there are two “depths”. We try to explain that it’s not possible for the Depth Radial to be 2” and that that’s the Depth Axially! or the Length of Stroke! We have had to educate thousands of clients on the meaning and importance of the Depth Radial Dimension.

Making the situation more frustrating is that I’ve never seen a drawing with the Depth Radially called out specifically. Sometimes, you’ll have a Bore size and then another bore dimension to the “top” of the keyway. Other times it’s from the centerline of the bore and you have to divide it by two. It’s odd to us that this is not a standardized dimension and procedure.

We call the Depth Radially the forgotten Keyway Broach dimension because very rarely do clients know what we are talking about when we ask for it. Engineers with decades of experience need the dimension explained to them. But more important than the engineer is that the machinists and operators know what the Depth Radial dimension is and that on a CNC Broach Tool the capability to cut it is a Finite Dimension!

Example: the depth radial capability of our 3/8 internal keyway insert is .200” meant for a standard internal keyway. I had a first time user call saying the insert had ripped out of the pocket of the tool. After reviewing everything I remembered to ask what his Depth Radial was and he said his application needed .220”. He crashed because he did not think of this dimension and that how high our insert sticks up above the tool with clearance to cut is a Finite amount.

Understanding why the Depth Radial is important is because some jobs are NOT standard and need a deeper Depth Radial than our standard insert will do. We can special grind the widths of larger inserts that have more Depth Radial Capability, but that larger tool and insert must fit your bore size.

I see a gap in education here both on the machining and engineering side. Many engineers do not seem to grasp as they design that the standard Depth Radial for a internal keyway is half the width. They’ll arbitrarily make the Depth Radial more than it needs to be not understanding the issue with tooling this creates for the manufactures of their parts. Most cutting tool companies make standard tooling product lines for standard dimensions. When an engineer does a random dimension not in line with standard procedure expensive special tooling, one-offs, must be made costing more money and increasing lead times. For the broaching process in particular this “goof-up” is hard because the higher or farther an insert sticks up above the tool to cut the slot the more tool bar meat you need to support it.

Meaning if you have more depth radially you need a bigger bore to fit into because you need a larger tool body.

A broach insert for an internal keyway that sticks way high up above the broach tool and a large thick tool body and a small bore to fit, you just can’t make it all work. As they design engineers need to keep in mind that geometrically there are physical constraints on inserted broach tools, so we encourage them to make the Depth Radial standard.

Finally, you can use our broach tool and “step it over” to do wider keyways, but remember this possibility is limited by the Depth Radial capability.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631