A simple way to cut internal keyways without moving the part

Keyways are one of the most common internal features in machined parts, but for years, shops had to rely on secondary equipment like slotters, broach presses, or wire EDM to get them done. That meant extra setups, longer lead times, and more cost per part. With CNC broaching tools, internal keyways can now be cut directly on a lathe, during the same setup used to turn the rest of the part.

This process is called single-point broaching and it’s quickly becoming a go-to solution for job shops and production teams looking to save time and improve consistency.

How Lathe Broaching Works

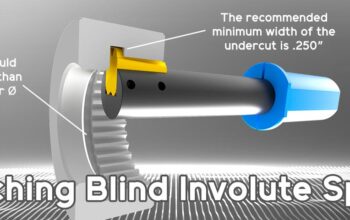

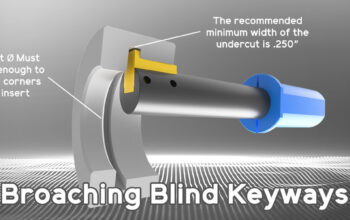

CNC lathe broaching uses a rigid toolholder and a carbide insert designed to cut a specific keyway profile. The tool is mounted in a turret or gang-style holder and aligned on centerline. A simple G-code program drives the tool into the bore using linear Z-axis motion.

Unlike traditional rotary cutting operations, the spindle remains off during the stroke. The tool advances slowly and removes material one pass at a time until the full depth and width of the keyway are reached.

Each stroke typically feeds between 0.0005″ and 0.002″. Once the cut is complete, the tool retracts, and the cycle continues.

Benefits of Broaching Keyways on a Lathe

The biggest advantage is eliminating a secondary operation. Keyways can be broached in the same setup as the turning cycle, reducing handling and eliminating the need to send the part out or move it to a manual broach press.

It also improves repeatability. Since the keyway is cut on the same machine using CNC-controlled motion, the form is consistent and aligns perfectly with other features already machined in that setup.

For blind holes, single-point broaching offers another advantage: it doesn’t require a pull-through like traditional broach bars. The tool can stop at a precise depth, allowing accurate keyways even in short or interrupted bores.

Is This Right for Your Application?

Single-point broaching is ideal for internal keyways in parts made from stainless, titanium, alloy steel, carbon steel, ductile iron, tool steel, or aluminum. It works well in both through and blind holes and supports everything from prototypes to full production.

The process is more controllable than older mechanical broaching methods. Once programmed correctly, it can run unattended and produce identical results part after part.

Simplify Keyway Cutting with CNC Broach Tools

CNC Broach Tools makes it easy to start broaching internal keyways on your lathe. Our inserted tooling system is designed for rigid, repeatable cutting on modern CNC machines, and our holders and inserts are built specifically for this type of operation.

Whether you’re cutting blind holes, tough alloys, or just want to eliminate a secondary setup, we can help you select the right toolholder, match the insert to your bore, and provide the guidance needed to integrate broaching into your existing process with confidence.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631