Blind splines are internal splines cut inside a bore that does not pass completely through a part. Because the tool cannot exit the back of the hole, blind splines require careful planning, proper clearance, and accurate programming. With the right approach, CNC machines can produce blind splines reliably using a controlled broaching process.

Blind splines are common in hubs, couplings, and drive components where a designer needs a torque-transmitting connection without an open through-bore. Although more challenging than standard spline work, they can be machined successfully on CNC equipment when relief and indexing are handled correctly.

Why blind splines need relief

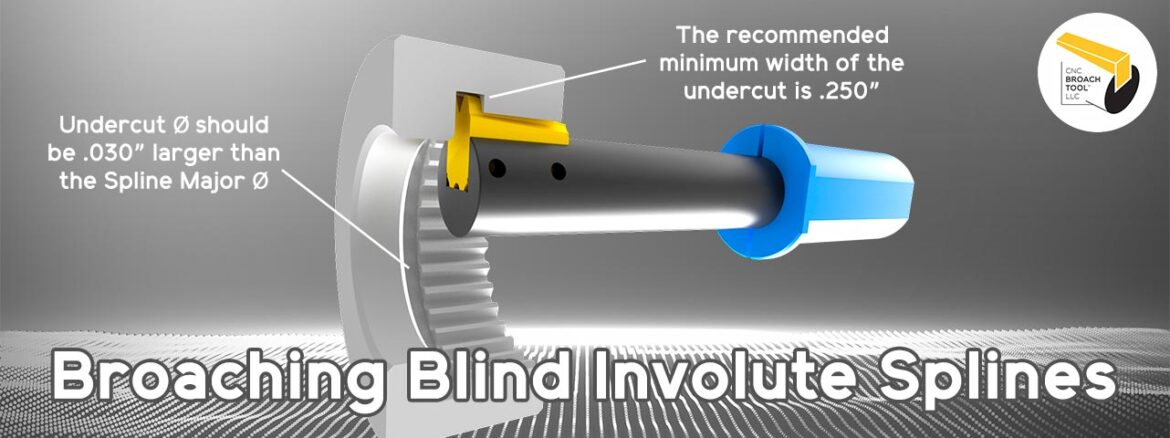

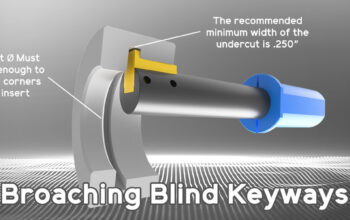

In a through hole, the broach tool can move completely past the part before retracting. In a blind bore, the insert has nowhere to exit unless a relief feature is added. Without this clearance, the insert compacts at the end of the cut, leading to chipped carbide, broken tooling, and excessive cutting pressures

Relief can be created with a turned recess or a machined pocket at the bottom of the bore. The relief must be large enough for the carbide insert to fully clear the cut before retracting.

How CNC broaching cuts blind splines

CNC Broach Tools uses a single carbide insert programmed for multiple passes. Each pass removes a small amount of material, which keeps forces low and predictable. Cutting each spline tooth requires feeding the tool into the bore, continuing into the relief area so the insert clears the material, retracting after clearing, and then indexing to the next spline position. This sequence repeats until all teeth are complete.

Indexing is typically handled through C axis rotation on a lathe or coordinate rotation on a mill. These methods ensure consistent spacing for every spline tooth.

Carbide tooling for blind spline work

Carbide inserts are ideal for blind spline broaching because they maintain sharp edges across multiple indexed passes and perform well in tougher materials such as stainless steel, alloy steels, and superalloys. Their rigidity also helps maintain consistent spline geometry at the bottom of blind bores.

Setup and programming considerations

Successful blind spline broaching relies on rigidity, alignment, and controlled tool motion. Key factors include:

- Secure toolholding to prevent movement during cutting

- Minimal tool overhang for improved rigidity

- Accurate centerline alignment to maintain consistent spline geometry

- Proper part clamping and verification of the relief area before cutting

Programming requirements include:

- Small incremental depths of cut to control load

- A Z endpoint that enters the relief area so the insert fully clears

- Retraction on the correct axis to avoid rubbing

- Accurate indexing to maintain even tooth spacing

- Consistent feed settings for uniform spline profiles

The value of CNC broaching for blind spline production

Modern CNC broaching allows shops to produce blind splines without dedicated broach machines or costly custom tools. When relief, rigidity, and programming are handled correctly, the process delivers accurate, repeatable spline geometry directly inside standard CNC equipment.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631