Tapered keyways present unique challenges when it comes to broaching on a CNC machine. Unlike straight keyways, the taper requires careful planning to avoid insert interference, depth errors, or tool damage. At CNC Broach Tools, we want to outline the best practices to help machinists achieve clean, accurate results while protecting their tooling investment.

Recommended Broaching Direction

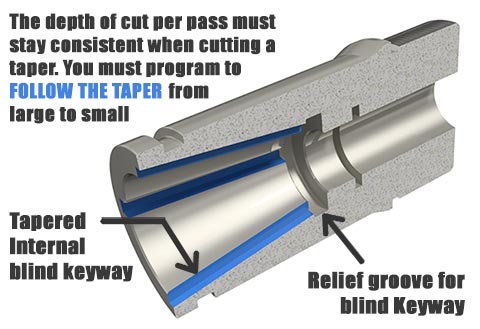

When cutting a tapered keyway, we recommend broaching from the large side and tapering smaller. This ensures the cutting insert maintains proper clearance throughout the pass, preventing drag against the ceiling of the keyway. The depth of cut per pass must stay consistent when cutting a taper. When programming a tapered key, the program must follow the taper.

In cases where the application requires broaching from the small side toward the big side, we do not recommend exceeding a 3° taper. Anything steeper risks reducing clearance to the point of insert rubbing, poor finish, or premature wear.

Staying Within Maximum Radial Depth

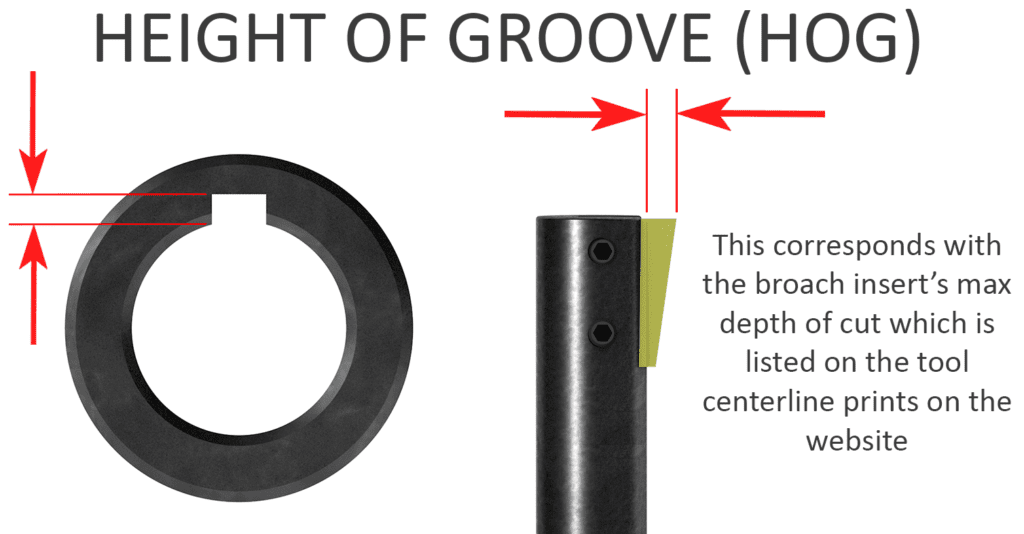

Every broach insert has a maximum allowable radial depth, which must never be exceeded. We refer to this as the Height of Groove (H.O.G.) dimension.

When broaching a straight keyway in a tapered bore, the radial depth of the cut increases as you go deeper into the part. It’s critical to monitor this change—if the H.O.G. dimension is surpassed, the insert will be overloaded, leading to breakage or scrap.

Always confirm the depth of your tapered keyway relative to the insert’s maximum rating before programming your cycle.

Programming Guidelines

- Start Ahead of the Part: Begin each broaching pass at least 5/8″ in front of the part (Z-axis).

- Exit Beyond the End: Extend the pass .125″–.200″ past the end of the material, depending on available clearance. This ensures the full profile is cut cleanly.

- Drop Before Retracting: At the end of the taper, program the tool to drop down out of the keyway prior to retracting in Z. Never retract backward through the keyway—this risks damaging both part and tool.

Our CNC Broach Tools Program Generator is being expanded to include taper programming, making it easier to set up cycles with confidence. Stay tuned for future updates as we continue to roll out this functionality.

Key Takeaways

- Broach tapered keyways from big side to small side whenever possible.

- If cutting from small to big, limit taper to 3° or less.

- Monitor the H.O.G. dimension carefully—never exceed the insert’s max radial depth.

- Follow proper programming practices to protect both the tool and the workpiece.

By following these guidelines, machinists can reliably cut tapered keyways in CNC machines with precision, consistency, and longer tool life.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631