Blind keyways are keyways machined inside a bore that does not pass completely through the part. Because the tool cannot exit out the back of the hole, blind keyways require proper planning, relief, and programming to avoid insert damage and to produce a clean, consistent slot. CNC broaching makes it possible to cut blind keyways directly inside mills and lathes, as long as the correct methods and clearances are used.

Blind keyways are common in parts such as gears, hubs, couplings, and shafts where designers want a mechanical connection without an open through-feature. Although they can be more challenging than standard through keyways, they can be successfully produced on CNC equipment with the right approach.

Why blind keyways require special clearance

When broaching a standard through keyway, the tool moves past the end of the part and exits cleanly. This gives the insert room to retract before the next pass. A blind hole does not provide this natural clearance. Without space for the insert to exit, the chip will be packed at the end of the cut, leading to chipped inserts, tapered slots, or tool pull-out.

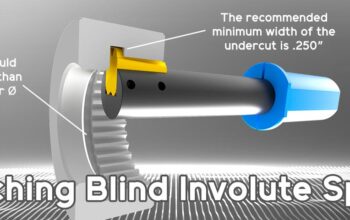

For this reason, every blind keyway must include a form of internal relief. Common methods include:

- A turned undercut at the bottom of the bore

- A milled relief slot created with a Woodruff cutter

- A drilled cross-hole that intersects the bore

Each of these creates a cavity where the broach insert can safely transition out of the cut before retracting into the bore and moving back toward the starting position.

How CNC broaching cuts blind keyways

CNC Broach Tools uses a single carbide insert programmed for multiple passes. Each pass removes a small amount of material, so forces remain controlled and predictable. On a blind keyway, the program must extend the Z travel far enough to allow the insert to clear the slot into the relief area. This ensures clean cutting without dragging.

A typical blind keyway cycle includes:

- Positioning the tool at the programmed approach distance

- Feeding into the bore until reaching the relief area

- Moving slightly deeper into the relief so the insert fully clears the material

- Retracting slightly below the bore diameter

- Retracting in Z only after the insert is out of the cut

- Repeating for each pass until the full depth is achieved

This controlled sequence protects both the insert and the machine.

Carbide inserts for blind keyway broaching

Cutting blind keyways places a premium on tool strength and reliability. Carbide inserts are ideal because they maintain a sharp cutting edge over long runs and resist wear even in tough materials like stainless steel or Inconel. Their durability supports the multi-pass cutting strategy used in CNC broaching, giving machinists clean results without excessive tool changes.

Setup requirements for successful blind keyways

Rigidity and alignment are critical in blind keyway broaching. The following setup steps help ensure accuracy and protect the tooling:

- Use hydraulic holders or precision split sleeves to secure the tool

- Keep tool overhang to a minimum

- Dial in the broach holder so the insert is on the correct centerline

- Confirm the part is clamped securely and parallel to the machine axis

- Inspect the relief area to ensure it is wide enough for full insert clearance

A rigid setup reduces vibration and prevents taper, especially in deeper blind bores.

Programming considerations

Several programming details contribute to successful blind keyway cutting:

- Program enough Z travel to allow complete insert clearance

- Use small depths of cut per pass, typically between 0.0008 and 0.0015 inch

- Start the broach cycle from a distance in front of the bore to allow the machine to reach full feed

- Retract on X or Y before retracting in Z to avoid rubbing

- Use exact stop commands when needed to to completely stop at a corner or a specific point before moving to the next command

Accurate programming ensures smooth cutting, protects the insert, and prevents loading in the relief pocket.

Why CNC broaching blind keyways is effective

Blind keyways once required die-sinking, specialty slotting machines or slow manual methods. CNC broaching allows shops to produce these features in-house using their existing equipment. With carbide tooling, a stable setup, and proper relief, blind keyways can be cut with the same consistency as through keyways.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631