ABOUT CNC SPLINE BROACHING

Carbide Broach Inserts with Spline Forms – Custom Made to order

All Spline Broach Inserts are a Special Grind with a Three Insert minimum order

Involute Spline Configurator

Using the Involute Spline Broach Configurator – Note: This tool is designed to work only for splines conforming to ANSI B92.1 standards

- Step 1: Choose the spline type – Internal or External.

- Step 2: Select the Pressure Angle (e.g. 30°, 37.5°, 45°).

- Step 3: Pick the Fit Type (e.g. Flat Root, Fillet Root, or Major Diameter Fit).

- Step 4: Choose the Tolerance Class.

- Step 5: Enter the Diametral Pitch (dp).

- Step 6: Enter the Number of Teeth.

- Step 7: Enter the Length of Cut.

- Step 8: Press the “Quoting Info” button

- Try the full version of CNC Machinist Calculator Ultra

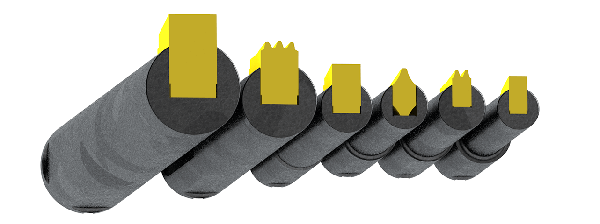

Carbide Spline Broach Inserts fit our standard Keyway Slotting Tools, and have TWO carbide cutting edges.

Please read this Blog Post which describes the information we require for quoting. If you are broaching a spline per ANSI B92.1 the information can be copied and pasted from the configurator to the left.

To receive a quote for Spline Inserts, please contact us though our contact form. See this blog post to learn more about what we require for quoting.

- CNC Broach Tools will review your drawing.

- If our products are a fit for your application, we will provide a quote.

- An approval drawing will be provided within a few days after placing your order.

- The standard lead time for Spline Broach Inserts is 21-28 days (days to ship).

- Expedite options are available with lead times as fast as 7-10 days.

Understanding Spline Data for Accurate Broach Quotes

When requesting a spline broach quote, it’s critical to include all relevant spline data. Each spline’s geometry — including pressure angle, number of teeth, pitch diameter, and fit class — determines the correct involute spline form and tool geometry. Missing or incomplete spline data often leads to quoting delays or incorrect tool designs. Our Spline Data Guide explains how to interpret an ANSI B92.1 data block and identify key parameters such as major and minor diameters, circular space width, and tooth thickness.

CNC Broach Tools also supports a wide range of global spline standards, including ANSI B92.2M, DIN 5480, DIN 5482, JIS B 1603, SAE, and ISO 4156. By providing complete and accurate spline data from any of these specifications, customers help ensure that every CNC spline broach is designed and ground to meet exact dimensional and fit requirements for both inch and metric applications.

Reverse Engineering Splines and Gears

If your part lacks documentation or spline data, CNC Broach Tools offers professional reverse engineering services for splines, gears, and serrations. Using high-precision optical measurement and CAD modeling, we can accurately capture spline geometry from existing components — even when the original drawings or standards are unknown. Our process identifies every critical dimension, including pitch diameter, form diameter, and involute form, allowing us to reproduce or improve legacy parts. Learn more in our detailed guide on Reverse Engineering Splines and Gears.

Whether you need to quote an ANSI, DIN, JIS, or ISO spline, or simply have a part sample, we can determine the correct form, create an accurate model, and produce custom carbide spline broach inserts that deliver precise and repeatable results.

Programming and Machining Involute Splines

Modern CNC lathes and mills make involute spline broaching more efficient than ever. Our online Guide to Broaching Involute Splines covers everything from setting up your tool paths to optimizing feeds and speeds. Using the right program parameters, machinists can broach internal or external splines directly in their CNC without the need for expensive pull broach machines.

In many cases, shops can even broach skip-tooth splines, leaving every other tooth uncut to reduce machining time or meet specific design requirements. External spline broaching is also possible with our carbide spline inserts and holders — ideal for parts that need both internal and external features in the same setup. The ability to broach a complete involute form on a CNC machine greatly reduces tooling costs and lead time compared to traditional methods.

From Serrations to J500 Splines

Beyond involute splines, CNC Broach Tools also manufactures cutters for straight-sided serrations and SAE J500 spline forms. These profiles are commonly used in aerospace, automotive, and industrial applications for torque-transmitting connections where precise alignment and surface finish are critical. Our engineers can help you determine whether a serration, involute spline, or custom hybrid form best fits your application. Each insert is precision-ground to match the specified form and pressure angle, ensuring consistent tooth geometry and long tool life.

Broaching Blind Splines Near Shoulders

CNC Broach Tools also specializes in broaching blind splines, allowing shops to cut precise spline forms in parts that cannot be broached through. Using our carbide inserts, machinists can broach internal or external splines adjacent to a shoulder as long as a small clearance relief is provided. We recommend a minimum .125″-wide relief groove to allow chip evacuation and full tool clearance at the end of the stroke. This technique enables blind-spline machining in complex components such as transmission shafts, couplings, and aerospace drive hubs—without resorting to costly secondary operations. By combining modern CNC spline broaching with proper groove design, manufacturers can achieve full-form involute or serration profiles even in tight-space applications.

The Evolution of Broaching Technology

Traditional broaching required massive pull-broach machines costing tens or even hundreds of thousands of dollars, with long, dedicated tools that could only produce a single part geometry. Those machines demanded custom fixtures, large setups, and significant floor space — making spline production costly and inflexible.

Today, CNC spline broaching has changed everything. By using our carbide insert tooling on a standard CNC lathe or mill, shops can produce internal keyways, involute splines, serrations, and external profiles on demand, using short cycle times and minimal investment. This modern approach not only reduces cost but also gives machinists the flexibility to broach a wide variety of spline forms with just a few tool changes.

Contact Us

Contact Us (877) 248-1631

(877) 248-1631